Free Advice & Recommendations

Free Advice & Recommendations

Free Technical Backup Service

Next Day Delivery & Worldwide Shipping

At AV Industrial Products Ltd, our team specialise in the design, manufacture and supply of anti vibration mounts, rubber mounts and engineering components. We offer a vast range of anti vibration mounts across the UK, ensuring you have the best vibration prevention available. With next day delivery available and highly competitive prices, browse our catalogue to find the perfect rubber mount for your application.

Anti Vibration Mounts, also known as rubber mounts, are used to reduce vibration in industrial machinery and vehicles. They are an integral component used within a wide range of industrial applications to reduce vibration, increase machinery lifespan, protect surrounding structures and improve operator comfort.

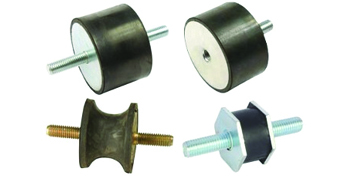

Our standard range of AV mounts includes Rubber Bobbin Mounts, Captive Mounts, Rubber Buffers and Bump Stops, Hydro Mounts, Cone Mounts, Shock Mounts and many more rubber to metal bonded anti vibration mountings.

If you need any assistance, please email our team or give us a call and we'll do our best to help.

AV Industrial Products Ltd offer a comprehensive technical engineering service to support you with your mounting selection and help to solve your vibration control issues.

Our bespoke services include computer-aided modelling and AV Mount selection, rubber mount testing, vibration testing and site surveys, and also in-house product testing to ensure product compliance and customer satisfaction.

We offer standard and bespoke anti-vibration mounts designed with durability and performance in mind. With load capacity ranging from 1kg to over 5000kg, we can supply you with mountings that reliably isolate and dissipate vibrations. Ensuring your equipment and machinery work to the highest standards.

Rubber Mounts are an effective anti-vibration mounts used within a wide range of industrial machinery and applications, including Cab Mounts, Engine Mounts, Marine Engine Mounts, Suspension Bushes, Generating Set Mounts and Shock Mounts.

Here at AV Industrial, our team are able to manufacture bespoke rubber mounts suited to your requirements. Our qualified applications engineers have a range of tools at hand to help you design and select the best anti vibration mounting solution for your application.

• Expert Engineering & Design team (over 50 years)

• In house testing facility to ensure product conformance

• Computer modelling & simulation (6 Degree of Freedom)

• FFT Vibration analysis & site surveys

• Testing of rubber components, including dynamic fatigue/endurance testing

• Solidworks 3D CAD & Finite Element Analysis (FEA)

Anti-Vibration (AV) Mounts typically consist of a rubber element bonded to steel fixings. The rubber component, often made from natural rubber, provides a flexible mounting system to minimise vibration, while the steel fixings enable the AV Mounts to be securely attached to both the equipment and supporting structure. For highly corrosive environments, such as offshore locations or the food industry, stainless steel Anti-Vibration Mounts (AISI304 and AISI316) are available.

The core concept of vibration isolation relies on selecting an Anti-Vibration Mount with a natural frequency at least half that of the disturbing frequency, such as the operational speed of a diesel engine. Our team of vibration specialists is available to help you choose the ideal AV mounts for your application, ensuring optimal performance, extended equipment lifespan, and cost-effective solutions.

Our Anti-Vibration Mounts range from small instrument mounts, designed for delicate sensors and instruments weighing less than 500 grams, to large heavy-duty mounts used in the construction industry, capable of supporting over 30 tonnes per mounting. These mounts serve three primary purposes: vibration reduction, shock protection, and suspension systems.

Our experienced applications team has extensive knowledge across various industries, including Power Generation, Construction, Earth Moving & Mining and Industrial Vehicles. If you need any help or guidance, please get in touch.

When selecting the appropriate rubber engineering components, there are many factors to consider that will ensure the trouble free service life of your equipment. For example, to help ensure that you achieve a prolonged service life, it is important that the mounts operate within their design stress and strain levels.

If the equipment static loadings or shock loadings exceed the anti-vibration mount design stress or strain levels, this could impede the service life of the rubber mount. Our qualified engineers can assist you with the mounting selection process ensuring that a suitable product is used for trouble free and prolonged service life.

Got any questions? Take a look below at our find frequently asked questions to some of the most common queries;

Anti Vibration Mounts, or rubber mounts, are industrial rubber components used within industrial machinery and vehicles to reduce vibration being transmitted into surrounding structures. The rubber component helps to absorb these vibrations and dampen the damaging effects that the vibrations impose.

As a general guide, using correctly selected anti vibration mounts, it is typical to achieve a minimum of 70% vibration reduction, however in certain instances it is possible to achieve 90%+ with certain products and in certain applications. Consult our engineers for specific technical advice.

Rubber Mounts are commonly manufactured from natural rubber due to its superior resilience properties which are ideal for reducing vibration transmission. For certain applications synthetic rubber mounts are utilised, such as Neoprene Rubber Mounts which provide improved resistance to oils and elevated temperatures.

Specially formulated rubber compounds can be manufactured for shock absorption, such as Shock Mounts, which provide increased levels of damping. In addition, Spring Mounts(manufactured from a steel coil spring) are available for slow speed applications or where high levels of vibration reduction are required.

Different anti vibration mounts are best suited for different applications. Your choice of anti vibration mount will depend on many factors, including the size, type, weight, application and vibration frequency of your machinery, just to name a few.

For more details on selecting the correct anti vibration mount, take a look at our comprehensive guide. Still looking for more information? Give us a call or email our team who will be able to help.

Anti vibration mounts are suited to a number of applications. Our products are used across a wide range of industries, from construction and off-highway vehicles to military and defence, we manufacture and supply a range of styles and sizes of av mount.

Whether you are trying to install your machinery with levelling feet, or install cone mounts to improve operator comfort within your vehicle cab, our anti vibration mounts are perfect for reducing vibration.

Being a leading manufacturer of anti vibration mounts in the UK, we supply a vast range of rubber mounts from our 25,000sq/ft head office, based in Leicester. Whether you are looking for standardised marine engine mounts or bespoke hydro mounts, we have you covered.

Within our product pages, you will find information and data sheets for each type of anti vibration mount. Within this information, you will find the advantages of each mount, along with their ideal application, dimensions and deflection data. For further information, email or call our team and we will be happy to help.