Vibration is an inevitable consequence of movement within machinery and equipment. These vibrations can have damaging effects that can lead to increased wear-and-tear if not managed and controlled. One simple solution to mute these vibrations is rubber mounts. Rubber mounts are specially designed and commonly installed onto machinery and equipment to reduce the transmission of harmful vibrations.

Vibration: What is it?

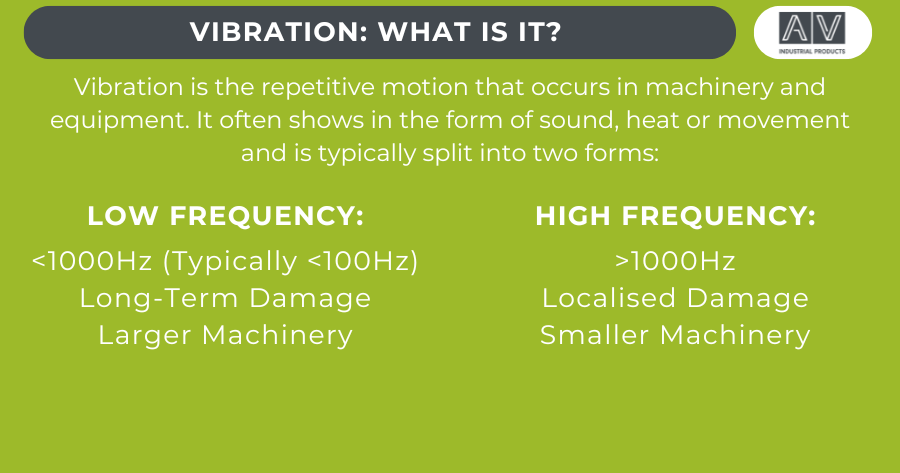

Vibration is essentially an oscillatory motion that can occur in any mechanical structure. The sources of vibration can vary widely, from rotating components like engines and motors to external factors such as environmental disturbances. Vibration is typically characterised by its frequency, with the easiest separation being ‘Low’ and ‘High’ frequencies.

Low Frequency Vibration

Low frequency vibrations occur at fewer cycles per second, typically below 100Hz. These often result from reciprocating equipment such as engines, and can lead to long-term, damage if not managed properly.

High Frequency Vibration

These are vibrations with a higher number of cycles per second, typically over 1000Hz. This type of vibration often causes quicker and more localised damage to machinery, such as spalling. High levels of friction, heat and noise are also common features of high frequency vibrations.

Although posing different threats and challenges, both vibration frequencies need to be detected, diagnosed and managed to prevent avoidable damage.

The Role of Rubber Mounts

Rubber mounts, also known as anti-vibration mounts, are designed to isolate and absorb vibrations. They are used across a range of industries, from construction to heating and ventilation to military and defence.

Here’s how they work:

Vibration Isolation

Rubber mounts act as a decoupler between the vibrating component and the structure it is mounted on. The rubber material allows it to absorb and dissipate the energy generated by vibrations, preventing it from transferring to the surrounding surfaces. This isolation reduces the amplitude of vibrations, therefore minimising their impact. The basic theory of vibration isolation is that the natural frequency of the mounting should be at least 2 time lower than the distributing frequency of the equipment. Our team of engineers can support you with calculation and simulation of vibration frequencies.

Energy Absorption

The unique properties of rubber enable it to absorb a significant amount of vibrational energy. When a vibrating force is presented, the rubber deforms and absorbs the energy, converting it into a small amount of heat. This process dampens the vibrations, effectively reducing their intensity. Our rubber products are designed with varying levels of damping, depending on the application they are design for, whether it be a vibrating screen with low levels of damping in the rubber, or a mounting with high damping for absorb shock energy.

Shock Absorption

In addition to vibration control, rubber mounts also provide excellent shock absorption. They can absorb sudden impacts and shocks, protecting sensitive components from damage. This is particularly important in applications where machinery is subjected to dynamic loads or high shock forces.

Types of Rubber Mounting

The type of rubber mounting will differ depending on the demands and applications of your machinery. At AV Industrial Products Ltd, we manufacture and supply a wide range of rubber mounting products that are suited to various applications. Some of the most popular rubber mounts include:

Rubber Bobbin Mounts

Also known as cylindrical bobbins, these are most commonly used within smaller equipment and appliances to absorb vibrations.

Captive Transit Mounts

This universal rubber mounting solution is cost-effective, high performing and easy to install. Our captive transit mounts are able to accommodate loads from 40kg all the way up to 1600kg.

Hydro Mounts

Hydro mounts offer a unique design that offers excellent vibration reduction of up to 95%. These rubber mounts are often suited to lower frequency, larger applications such as off-highway vehicles or operator cabs.

Cone Mounts

Cone, or cab, mounts offer high horizontal stiffness compared to the vertical stiffness in order to control the movement of Engines, Cabs and Equipment. With a failsafe design, they are ideal for mobile applications.

These are only a few examples of the types of rubber mounts that help to reduce vibrations. Take a look at our entire product catalogue and find the perfect mounting for your use. If you need any help or have any questions, please get in touch using our contact form or give us a call.