Guide to Mounting Selection

Simple 6 Steps Guide to Mounting Selection:

- Determine the total weight of the equipment & number of mountings required

- Calculate the weight on each mounting (Consider that weight may not be evenly distributed)

- Determine the running speed (or forcing frequency) of the equipment.

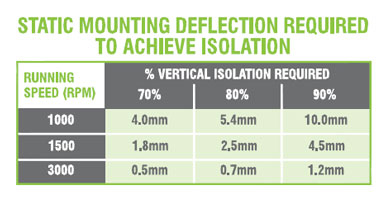

- Determine the static deflection of the mounting from the chart below (Generally 70% Isolation is acceptable for most applications)

5.Based on the load per mounting, select a suitable mounting type to give the required static deflection, taking into account the specific application requirements, such as whether the equipment is Mobile or Static.

6.Ensure that all connections & services to the equipment, such as exhausts, pipework and ducting are flexible in order to allow the equipment to move freely

In addition, other factors that should be taken into account, such as:

- Contamination with Oil, Fuel, Chemicals & extreme Temperatures

- Corrosive Environments – Off Shore Rigs, High Humidity.

- High G forces – Off-Road Vehicles, Construction Plant, Military

- Shock Protection – to protect fragile equipment from drops & impacts.

- Foundation should be Level & Flat. Extra care is required for Suspended Floors

- Suspension Springs to accommodate movement. I.e. Vibratory rollers, compactors, screens

- Low Speed Equipment – Fans, Chillers, Blowers & Air-Conditioning Units.

- Trunion Bushes & Suspension Bushes – Angular & Torsional Movements

- Human Vibration – i.e. ISO 2631

- Mechanical Vibrations – i.e. ISO7919 & ISO10816

We offer a full technical & engineering back up service. If you would like help in selecting suitable mountings for your application, please contact our technical department for assistance.