Excessive and consistent machine vibration can be problematic in both the short and long term for your equipment. While vibration issues can arise from loose bolts or worn components, they are often an inherent part of a machine's operation, especially in reciprocating machinery like engines, pumps and motors.

In this article, we will explore the common causes of machine vibration that are intrinsic to mechanical operation, focusing on vibration in reciprocating machinery and how these challenges can be managed effectively.

What is Vibration and Why Does It Occur?

Vibration refers to the repetitive back-and-forth, side-to-side or up-and-down movement of a machine component around a central point. In reciprocating machinery, such as internal combustion engines and piston-driven pumps, vibration is an unavoidable by-product of their mechanical function. It can generally be categorised as:

-

Free Vibration: Natural vibration occurring without continuous external forces, like a pendulum's swing.

-

Forced Vibration: Driven by an ongoing external force, such as the rotational movement in motors.

-

Damped Vibration: Where external factors like friction reduce the amplitude of vibrations

Common Causes of Vibration in Machinery

Unlike general machinery, reciprocating engines and pumps experience vibration due to their operation.

Out-of-Balance Forces

Reciprocating machines have in-built components such as pistons, crankshafts and connecting rods that generate oscillating forces. These forces ideally balance out during operation, but any deviation in mass distribution, wear or assembly misalignment can lead to an imbalance.

These imbalances amplify the oscillating forces, resulting in increased vibration. For instance, a four-cylinder diesel engine running at 1500 RPM produces a dominant second-order vibration harmonic at 50 Hz due to the difference in inertia forces during each piston’s upward and downward stroke. If one cylinder experiences wear or a connecting rod becomes misaligned, the harmonic imbalance intensifies, further increasing the levels of vibration.

Gas Fluctuations

During the combustion process within engine cylinders, rapid gas expansion occurs. The pressure is constantly changing and combustion forces vary with cylinder configuration and firing order, creating cyclic forces that generate vibration.

These fluctuations are particularly significant in multi-cylinder engines with complex firing sequences. Additionally, incomplete combustion or irregular firing can lead to sudden pressure spikes, further increasing vibration. Over time, natural wear and tear of valve seats, piston rings or injectors can exaggerate these fluctuations.

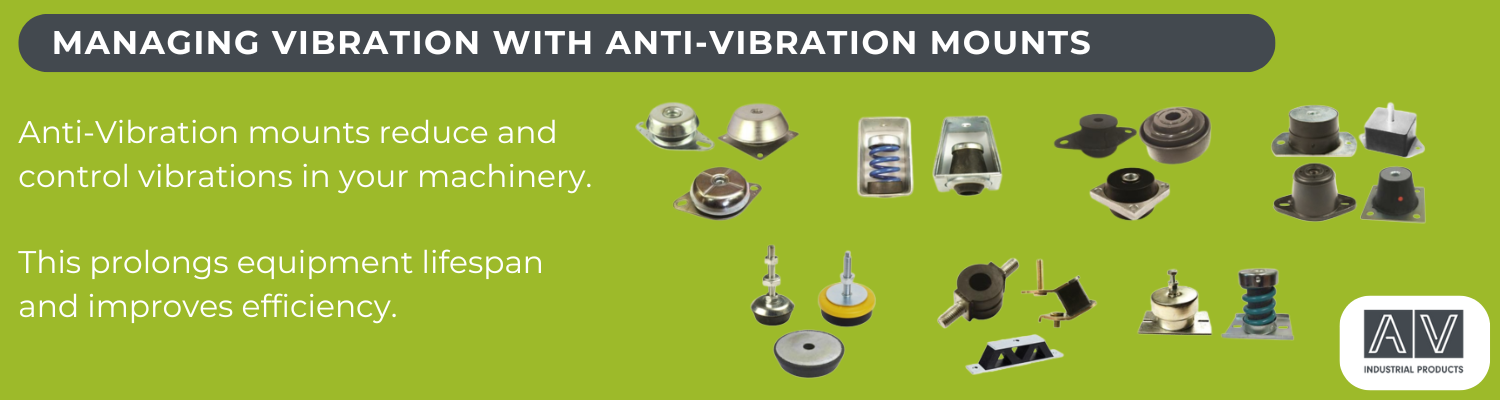

Managing Vibration With Anti-Vibration Mounts

While it is impossible to remove vibration entirely in reciprocating machinery, it can be controlled. Selecting and installing the correct anti-vibration mounts can reduce excessive vibration typically by 70% to 95%. These specially designed mounts are engineered to absorb and isolate vibrational energy, reducing its transmission to the surrounding structures.

Anti-vibration mounts work by converting kinetic energy from vibrations into a small amount of heat, dissipating the energy safely. They also help to stabilise machinery and prevent excessive movement that can cause structural damage.

By selecting the correct type, size and load-bearing anti-vibration mount, you can control vibration, extend equipment lifespan, reduce noise levels, and maintain performance efficiency. Take a look at our comprehensive selection guide or get in touch with our team.

How Can AV Industrial Products Help?

Having decades of experience in designing, manufacturing and supplying anti-vibration mounts across the UK, our team is well-equipped to help. Whether you are looking for a specific product to reduce vibrations or a vibration survey and analysis to help diagnose your machine issues, get in touch with us.

As experts in vibration, we take pride in providing expert advice and excellent customer service to our esteemed clientele. Our team is available to call anytime between 8:30am and 5pm, or send us an email and we’ll get back to you. Whatever you need, we are here to help.