Anti-vibration mounts, also known as rubber mounts, are used in industrial machinery and vehicles to reduce vibration. AV mounts also have other benefits, such as reducing noise, increasing machinery lifespan and improving operator comfort. They are an integral component within a wide range of industrial applications

Anti vibration mounts are fastened onto machines and vehicles with the primary function of suppressing vibration and noise. Vibrations from equipment and vehicles have numerous negative impacts, such as noise pollution, environmental damage and potential operator injury.

AV mounts are typically made of rubber or a combination of rubber and other materials. Rubber mounts are used within a wide range of industrial applications as they have excellent shock absorption and vibration-dampening properties.

Rubber anti-vibration mounts have become a staple within a range of industries, from construction to HVAC systems to military and defence. AV mounts are a necessity in the modern industry.

AV Industrial is proud to be a specialist manufacturer of anti-vibration mounts for over 30 years, supplying a wide range of anti-vibration mounts, suitable for any application.

Why Are Anti Vibration Mounts Important?

The correct anti vibration mount type is vital for the smooth and safe running of any piece of machinery or any vehicle. Vibrations can have numerous unwanted effects on machinery and the surrounding environment such as:

-

Damage to machine parts

-

Transmitting noise pollution

-

Operator discomfort

-

Shortened lifespan of a machine or vehicle

-

Loosening of screws and bolts

Anti-vibration mounts are easy to mount and provide a durable solution to effectively dampen vibrations. When your machine or vehicle is being used, the mount absorbs the vibrations, significantly reducing and minimising the negative effects, such as noise and damage.

The role of anti-vibration mountings is not to prevent vibration but to control and reduce it. They are the perfect cost-effective solution to counter excessive vibration and ensure your machine, operator and environment remain safe.

How to Choose the Right Anti Vibration Mount

Anti vibration mountings come in all different shapes and sizes to fit onto all types of industrial machinery and vehicles. Every mount itself is also available in a range of sizes to accommodate different weights and environments, ensuring that every machine is catered for.

When selecting your anti-vibration product, it is important to buy quality products from reliable manufacturers. If you settle for a cheaper product, they may be less effective in protecting your machine and run the risk of causing further costs in the future.

To find the perfect anti-vibration mount for your machine, there are questions you can ask to find the appropriate product:

1. How Much Does the Machinery Weigh?

This will give you an idea of the number and size of mounts you need. The heavier the machine, the larger the mounts or, the number of mounts needed.

2. What Weight do you Need for Each Anti Vibration Mounting?

If the weight is evenly distributed across the machine, you will need equal weighted mounts. For instance, if your machine is 320kg, you can use four mounts, each mount supporting 80kg. Be sure to check the centre of gravity in case it is not even.

3. What is the Machine’s RPM (Revolutions Per Minute)?

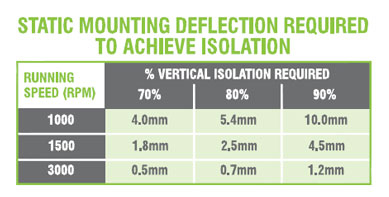

Calculate the running speed of the machinery either manually or by checking the machine’s handbook.

4. What is the Mounting’s Static Deflection?

Static deflection is the amount your mount will compress under the weight of the machine. The more static deflection, the more work the mount has to do. Generally, a 70% isolation is acceptable for most applications.

5. Which anti-vibration mount do I need?

Based on your previous information, you can now choose the mounting type and the dimensions that give you the ideal static deflection.

If you are still unsure, our team of experts are always happy to help, so please get in touch.

Types of Anti-Vibration Mounts:

Rubber Bobbin Mounts:

Rubber Bobbin Mounts are a low-cost solution to reducing vibration and shock. These mounts come in a variety of types, including Male Male, Male Female, Female Female, Waisted, Hexagon and Profile. They are used throughout industry and within a wide range of applications to reduce vibrations that cause damage or instability.

Bump Stops:

The main purpose of a bump stop is to serve as a cushion, protecting your machinery against impact shocks from external moving components. Bump stops, or rubber buffers as they are also known, are one of the most popular anti-vibration mounts used within machinery. Many of them are used in suspension for vehicles.

Captive Transit Mounts:

Captive Transmit Mounts are specially designed to control movement of the mounted equipment during transit. This type of mount is ideal for mobile equipment but is also suitable for static applications. The rubber used offers vibration reduction of up to 95% in all axes and the mount itself can load ratings from 20kg all the way up to 5000kg.

Marine Engine Mounts:

Marine engine mounts were originally designed for use with marine propulsion engines, however, they have now become popular throughout a wide range of industries. They are specially designed to reduce the vibration of the engine from the hull of the vessel, increasing comfort and reducing wear and tear of the machinery.

Flanged Circular and Rubber Mounts:

Flanged mounts come in both circular and rubber variations.

Flanged circular mounts are often used as engine and alternator mountings within the power generation market. These mountings are low-cost, provide good levels of vibration reduction and have great shock absorption properties in vertical and horizontal planes.

Flanged rubber mounts are more typically used within heating, ventilation and air conditioning (HVAC) systems. They offer high levels of deflection, are good for isolating vibrations and due to their low cost design, they are perfect for static applications.

Levelling Feet:

Adjustable levelling feet are designed to keep your machinery levelled. They provide stability and balance to your equipment and machinery whilst being easily adjustable to cater to different elevations. Alongside stability, the rubber base of the levelling feet provides vibration and noise reduction. At the same time, reducing movement due to its increase in friction with the floor.

Spring Mounts:

Spring mountings are a high-performance product with the ability to reduce up to 99% of vibrations. They come in two distinct types: enclosed spring and open-spring mounts. Spring mounts are particularly beneficial for slow-speed equipment (less than 1000 RPM), such as HVAC equipment and generators.

Acoustic Hangers:

Acoustic hangers are specialised suspension devices that minimise noise and control vibrations. They are used in buildings, structures and equipment to control vibration levels and minimise noise. Acoustic hangers have many benefits and are a common solution to combat building noise and vibration.

Cab Mounts:

Cab mounts are simple to install and can withstand high dynamic shock loads, making them particularly suitable for mobile applications. These mounts are typically used in industrial vehicles such as off-road (excavators and backhoe loaders) and agricultural vehicles (tractors and harvesters).

Instrument Mounts:

Instrument mounts come in a variety of styles and are suitable for different types of equipment and machinery. Low-frequency mounts are typically used for lightweight machinery, such as precision equipment, medical equipment and sensitive instruments. Whereas plate and pedestal rubber mounts can be used for marine equipment, radiators and more.

If you wish to know more details about any specific products, our expert team is happy to help.