If you handle power tools, you may be familiar with the term hand arm vibration (HAVS). If you work in an applicable industry, and you are responsible for managing the work force’s schedule, you will also be familiar with the term.

It often shocks people to hear how destructive excessive vibration can be. Not only can the introduction of unregulated vibration be debilitating for your work force, but ignoring it can land you in serious trouble.

The truth is, you have to consider hand arm vibration in the workplace. Moreover, you should have effective measures in place to mitigate the risks that come with it. This will ensure your employees are happy and safe, and will also ensure your facility is compliant with health and safety regulations.

Today, we are delving into hand arm vibration at work. We are going to define what it is, explore the risks associated with it and help you with creating and implementing prevention measures. Read on for more information.

Hand Arm Vibration at Work: An Overview

Here at AV Industrial Products, we create products that work to stop uncontrolled vibration in its tracks. So, why do we do this?

If machinery or equipment is left to create excessive levels of vibration and noise, it can cause your business, and workforce, a wealth of problems.

One of those is hand arm vibration. For those of you who don’t know, this term refers to an illness which people who use power tools and heavy machinery can develop. Of course simply using power tools is not enough to develop it. Rather, it is the use of power tools and equipment that create vibration without effective PPE and prevention measures such as anti vibration components.

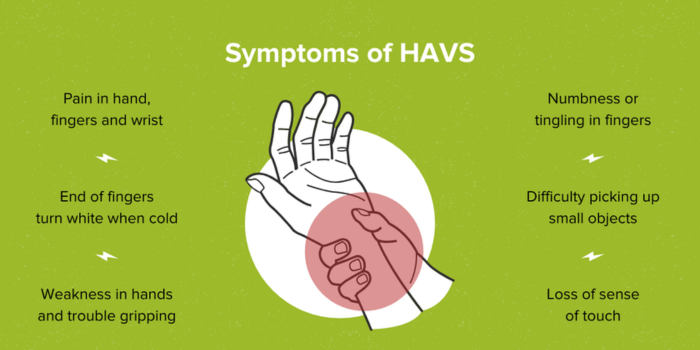

The government’s health and safety executive define it as ‘’the cause of significant ill health (painful and disabling disorders of the blood vessels, nerves and joints)’’. As you can see, it is a problem that has the potential to cause significant damage to your employees and business. Thus, putting sufficient vibration control measures in place is highly important.

Without these measures, you put your business at risk of receiving significant fines and even closure. Moreover, you risk the wellbeing of your staff.

We appreciate that those who may be new to the industry, or have limited managerial experience, may be confused at this point. We get it.

Thankfully, there are a wealth of resources available which define hand arm vibration, help you identify symptoms and give you a strategy to mitigate the risks. With experience in vibration control engineering, our team also has a wealth of knowledge around the topic. Continue below where we outline the most common and popular prevention measures.

Prevention Measures

Risk control is relatively straight forward. It requires foresight and planning, but once a strategy is implemented the rest will take care of itself.

One of the most important things is ensuring any equipment that produces vibration is regularly maintained and serviced. Not only does this mean your facility’s equipment is working efficiently, but it also means that any parts which may be causing excessive vibration are replaced.

Items like bump stops, for example, should be regularly examined to avoid metal on metal contact. This is one example, but there are plenty more examples of where rubber components can be utilised to reduce vibration.

With this comes putting measures in place to discard old equipment and replace it. This should be enforced as a company wide policy, and will reduce the risk of hand arm vibration at work.

Another tactic is to familiarise yourself with the symptoms of HAVS and ensure hand arm vibration syndrome treatment is swift. The damage can be permanent once developed, so try to identify members of staff with symptoms and ensure they are in an area of the business with less risk.

Other popular examples include the use of PPE. Personal protective equipment should be supplied anyway, but it is particularly important in environments where heavy machinery and equipment is being handled. Specialist anti vibration gloves are now available, although these should not be relied on solely. Keeping staff warm and dry will go a long way, as it encourages healthy blood circulation.

Finally, it is highly beneficial to create work schedules that are sensible. Regular breaks in problem areas should be encouraged and staff handling heavy equipment should be consistently rotated. However, it can also be noted that with effective anti vibration mountings the levels of vibration can be reduced and therefore allow the operator to use the equipment for longer - increasing productivity.

Helping You Comply With Hand and Arm Vibration Regulations

We hope you enjoyed the following article, and now have a greater understanding of how to prevent this issue.

As mentioned, anti vibration components in machinery work to reduce the risk of vibration wrecking havoc. Our team specialise in the creation and supply of such components. Thus, we are equipped to guide you on the best products and practices.

If you would like to talk to our team about our product offering, or to understand how we can help you prevent and manage vibration, we encourage you to contact us today.